Hip roof frame. Calculation example. The main elements of the tent truss system

Currently, in the construction of suburban residential buildings can be used the following types roof structures:

- single-pitched or double-pitched roofs;

- mansard roof;

- tent structures.

The most difficult for self-production is the last version of the roof, which, nevertheless, attracts many with its originality and attractive appearance. In this article, we will tell you how to make a hipped roof with your own hands, give drawings, photo and video instructions.

You can also use sheet metal or sheet metal, but then you need to consider a significant portion of these materials. The choice of cover material should be considered at the stage of investment plans, because in the case of hip covers, the actual costs are higher than at the beginning. This is due, in part, to the fact that more expensive than basic skin components must be applied to the resulting corners. Therefore, when deciding to cover a house with a hip roof, it is worth asking carefully what the final cost of manufacturing such a roof is, depending on the type of roofing used.

Device

The hipped roof is a special four-pitched structure with a square at its base, and the slopes are made in the form of isosceles triangles converging to this base.

Such a roof may have more slopes or be generally round, while the main thing is to observe symmetry. She reminds of appearance tent, which is captured in its name. It should be noted that the absence of gables in tent structures allows significant savings on materials during their construction.

These aren't expensive roofs, but they aren't the cheapest to consider at the design stage. In Poland, envelope roofs are quite popular, despite the fact that they create many difficulties in developing the attic space below them. They appear both in traditional construction and in modern architectural forms. They are also used to cover houses built in the attic. However, the most important thing in them is the rational arrangement and placement of chimneys and windows.

Attic under the envelope roof

It should be remembered that the chimney must be installed on the roof high enough to be able to create a corresponding line in it. The main task of windows is to illuminate, not just arrange, the surface under the roof of the envelope. Despite their attractive appearance and practicality, envelope roofs also have their drawbacks. It is imperative to create a series of bevels under their lands. This also means that the type of roof that in question, is most often used to cover one-story buildings where the attic is not intended for living quarters.

If desired, a roof in the form of a tent structure can be built on any building, although it is much more convenient if the base of the house is made in the form of a square.

The roof structure is based on a rather difficult rafter system, which, if you have certain skills, you can do it yourself.

In the case of homes where the attic needs to become a usable surface - designing that surface under the envelope is a real challenge even for an experienced interior designer. The most valuable space attic, that is, the highest height, is located in the center of the house outline and at the same time under the ridge. This, in turn, causes the windows to be fixed, or lucarne, which will light up the attic. A common solution is to design a lucarne on each of the roof slabs and complement them with slabs.

Often you can also find houses with more than one add-on on the same side. However, it is worth noting that such modified roofs look heavier than they really are, and excess glazing distorts the proportions of the entire building. Another option that creates the possibility of developing an attic under an envelope roof is the back of the roof on the wall. We know that this wall will be higher - this attic will become more functional. However, keep in mind that too high a knee wall can negatively affect the proportions of the body of the house.

Design calculation

When calculating the performance of a hipped roof, the following conditions must be taken into account:

When calculating the performance of a hipped roof, the following conditions must be taken into account:

- selected dimensions (length and width) of the base;

- angle of inclination of slopes;

- the shape of the base of the roof (it is desirable that it be a square).

Note that the execution of these works is best entrusted to specialists, since the quality and reliability of the entire structure as a whole will depend on their results.

Similarly, he also tries to increase the angle of the slope. Although this method gives the expected results for gable roofs, neither roof space nor satisfactory appearance grows with hippos. This is a type of envelope roof, or a hipped roof. But what makes it different from the traditional envelope is the lack of a comb. The roof top of the tent is shaped like triangles, with the tops dropping down to one of the highest points of the roof. The roof is always built on a square projection, which results in all four sides being the same size and often the same angle of inclination.

Roof installation

The hipped roof frame contains the following elements:

- diagonal rafters;

- support beam (Mauerlat);

- side and ridge runs;

- braces and braces.

When arranging a hipped roof, the following types of diagonal rafters can be used:

The appearance of the roof of the tent resembles a pyramid. As with envelope roofs, attic space is difficult to handle, so roofs of this type are most often used in square-pattern, one-story houses where the attic will remain an unusable surface. They are also used as cover for free standing garages or roof towers. These types of roofs with a slight slope are often used in the case of reconstructed ankles from years.

The most important function of the roof is to protect the house from adverse external factors - rain and snow, wind and low and high temperatures. In order for the roof to be strong and perform its task properly, the main issue is choosing the right scissor design.

- hanging type rafters resting on walls and creating a bursting force horizontally (used in the absence of internal load-bearing partitions);

- layered rafters, based not only on walls, but also on internal supports (bearing partitions).

In wooden frame structures, the entire truss system rests on the upper trim of the base of the building (in log cabins - directly on the upper crowns of the structure).

The simplest of them is the rafters. The beam consists of two rafters located on top of each other along the ridge line and on silt rafts, i.e. beams laid on the outer walls. Additional reinforcement is boards nailed to the rafters under an inclined, so-called. wind braces. However, usually the distance between the axes of the outer walls of the house is greater, so it is necessary to add a cross beam to the rafter connecting the rafters. An important advantage of the roof solution is the ability to lay the attic floor on beam beams.

At no additional cost, we acquire much-needed economic space. Another way to spread the load is in a purge trap. The principle of construction is to transfer pressure from the rafters to a horizontal beam, additionally supported by columns and racks. The columns are reinforced with their ties in the axis. This arrangement allows almost any adjustment of the angle of the roof. Unlike beam construction, where the load is transferred to the exterior walls of the building, the roof is primarily based on interior load-bearing walls in a purlin-clay structure.

In brick houses, a Mauerlat or a special support beam is used as a support, laid on walls prepared in advance for this. Their preparation usually comes down to leveling the surface of the upper row of masonry and pouring it with a screed. Sometimes (in order to better bind the Mauerlat), embedded elements are mounted on this surface.

This type of bedding is more economical when it comes to the amount of wood used. Bundles are also made of steel or reinforced concrete. Some manufacturers of wall system solutions also offer roof construction elements. However, solutions are still not popular in Polish single-family housing. Depending on the angle of inclination of the project roof, a suitable cover is selected for it. The rule of thumb is that the more flat the roof, the more uniform the lining should be. On roofs up to 35°, shallow coatings such as shingles are not used as this may cause leakage of individual coating elements.

On top of it around the entire perimeter of the building, support bars and beds are mounted, and a layer of waterproofing material is necessarily laid between the brickwork and the Mauerlat.

When preparing a hipped roof, you will need to use several types of roof trusses. First of all, these are slopes of the usual form, which are connected in the ridge. Additionally, side triangular and diagonal rafters can be used. During their installation, the main attention is paid to the absence of discrepancies in the length and angle of inclination of these elements, which must be clearly calibrated for all four sides. In this case, the length of the overhang is usually chosen based on the design features and can reach one meter.

most beneficial for flat roofs is roofing resin and angled 11th sheet or sheet metal. In each type of solution, manufacturers offer us a wide range of materials, colors and designs. Available in colorful sheets, rolled or cut into diamonds, trapezoidal sheet, metal sheet and ceramic metal coating. Even classic tiles are now available in traditional ceramic and lighter cement.

Outside the outer covering, the additional protection of the roof waterproofing is the so-called. precoat layer. It is laid on the formwork or directly on the rafters. Usually made of foil or resin, the pre-coating layer protects the roof from micro-leakage of water in places from sheet metal or tile factories. This prevents moisture from penetrating into the thermal insulation layer. To avoid the accumulation of water droplets on the surface of the film, the counters used on the rafters, which create a ventilation space along the entire length of the slab.

After installing the rafters, you can proceed to fixing the central (intermediate) ones. At the same time, one should not forget that they must be of the same size and placed strictly parallel. One of their ends is attached to the Mauerlat, and the other to the roof ridge.

After that, you can proceed to attaching the corner rafters to the diagonal rafters. For this purpose, a special sherd beam is installed on both sides of the rafters.

Its entrances are secured with special nets that prevent animals from nesting in the roof structure. Roof protection against water must be complemented by adequate protection of the building against heat loss. If the attic is not in use, only the ceiling above which it is located will be heated. However, if the attic has the appropriate height, it is most often used for living space. This entails the need for thermal insulation in the roof structure. It is usually made of mineral wool or polystyrene tiles.

A layer between the rafters, sometimes - to thicken the heat - using additional wood grating on the rafter railing. Keep in mind that the roof heats up much more than the walls, so its good insulation has big influence for the comfort of life. It is also important to maintain the continuity of thermal insulation, i.e. the cross-sections of the insulating material of the walls and roof are not interrupted at any point. This can lead to the formation of thermal bridges. They cause point cooling of the building, and consequently - the condensation of water vapor.

In order to increase the strength of the tent structure during installation, a transverse beam can be used to strengthen the central rafter system.

In conclusion, you just have to fill the crate and lay the roofing material.

Before laying the roofing, it is required to prepare a layer of insulation, as well as steam and waterproofing of the roof, and it is recommended to start such preparation with laying waterproofing. It is usually spread from bottom to top with sheets overlapping by 10 cm.

As a result of dampness, the walls can become dirty, and even the development of shapes and forms. Below the polystyrene or wool, a vapor barrier is applied, which prevents moisture from penetrating inside the house from inside the insulation layer. Then a finishing layer of boards, gypsum boards or chipboard is applied. Moisture protection materials must be provided in rooms with moisture in the attic, such as bathrooms or saunas.

In addition to protecting the building, the roof is a durable element of the architectural composition of the building. The aesthetic effect is created by the type and color of the cover, along with the detail of the finish: the gutter or the flashing of the chimneys. However, the roof is the most important. The most unusual modification roof truss buildings depending on whether we decide to adapt the attic for use or not. In addition, we can use elements such as bridgeheads and pedestals, front walls or attic structures.

A counter-lattice is stuffed on top, fixing the waterproofing system and forming a gap for ventilation of the under-roof space. On the inner (lower) side of the rafters, a heater is laid, covered from above with a layer of vapor barrier.

A photo

The photo shows various options hipped roof construction:

Instead of a simple gable roof, we can decide, for example, a tent roof that has as many slots as there are sides of a given building. In the case of twins or series buildings, we often encounter pitched roofs. Also important are the thinner elements of the roof, such as the loin, the will of the eye, and the skylights. Allows you to increase the space of the attic with a bay window with a vertical window.

This is an extremely picturesque architectural detail. However, attention should be paid to the quality of its construction and insulation. Because any intervention on the roof is subject to leakage or thermal bridging, the loom must be designed and built with great care. It should not be too dense - snow melt blocked between the roofs of the lucarne can easily lead to the destruction of the waterproofing layer of the coating. Because of the above requirements, and for economic reasons, skylights are much more common.

Their unmistakable advantage is the easy assembly, which consists in inserting the window between the rafters and fixing it to the roof structure with steel corners. If the truss works at the place where the hole is planned, at the place where the rafter insert is replaced, then there are transverse beams that reinforce the structure. Once the window frame is installed, the individual layers of insulation are sealed and their edges secured with protective flanges.

Just as when installing a roof window, chimneys and chimneys can be removed. Snowflakes are often placed on the edge of roof tiles and above windows. They are used to prevent sudden falls of large snow masses, which often ends in the destruction of the gutters. It is worth noting that, contrary to appearance, a certain amount of snow on the roof is beneficial for him, since it improves the thermal insulation of the building. Finally, let's say that the roof must also be equipped with a lightning protection system. It is not expensive, and its absence can have fatal effects in the future in the form of damage to roof components or home electrical installations.

Blueprints

The drawings provided show the various designs of the hipped roof. They can be taken as the basis for a future new roof:

The usual gable roof seems to some owners of suburban housing too banal and uninteresting, and they start looking for more original options. These include a tent construction, which looks extremely interesting from the outside, as if descended from illustrations in a history textbook or a book of children's fairy tales.

Despite its apparent simplicity, the hipped roof truss system is one of the most difficult to erect. Taking on the construction of such a structure on your own, without experience in such work, will be very risky. However, for those who wish to opt for just such a design, it will be useful to obtain information on the structure of the system, its main components, and on basic calculations. It is in this context that this publication will be built. We hope that it will help to understand the nuances of the tent truss system, realistically assess its complexity and the possibility of self-assembly.

In fact, a hipped roof is geometrically a “classical” pyramid, that is, a figure with a polygon at the base and faces that are isosceles triangles converging at a single vertex.

In private construction, a pyramid with a base in the form of a quadrangle is most often used, although for extensions (turrets, bay windows, etc.) or light garden buildings (arbors), the construction of more complex structures is practiced, in which the base may also have the correct six- or octagon (sometimes even more).

In this publication, the emphasis will still be on the hipped roof. Here, too, variations are possible. A "classic" is a pyramidal structure based on a square base, with a vertex located on a perpendicular passing through the point of intersection of the diagonals of the base. In this case, all four slopes will be absolutely congruent triangles located at the same angle of inclination.

The figure-scheme shows a pyramid with a square at the base - this is what we will consider in the future. You will have to return to this drawing more than once in the course of the presentation.

It is quite possible to use the tent scheme on a rectangular building, in which the length exceeds the width. However, in practice this is rarely used - due to the unnecessary complication of both calculations and installation. With this option, the slopes, based on a shorter wall, become longer and have a smaller angle of inclination to the horizon, that is, the external loads for them already have to be calculated individually. For rectangular bases, a hip roof is much more suitable - it is in many ways similar to a hip roof, but it is better adapted to just such conditions.

The hipped form of the roof provides many significant advantages:

- A house with such a roof stands out very advantageously against the background of standard gable roofs, having a peculiar appeal.

- In terms of its aerodynamic qualities, that is, its ability to withstand wind loads, especially during squally or even hurricane gusts, it is perhaps unmatched among pitched roofs. Moreover, the lifting component of the wind load is minimized - the effort that tries to tear the roof up.

- The unique pyramidal shape contributes to the uniform distribution of all external and internal loads on the roof system and the building as a whole.

- With proper insulation of roof slopes, such a roof - optimal solution in terms of energy saving.

- With the optimal choice of the steepness of the roof slopes, there will be no particular problems with snow drifts.

The disadvantage, in addition to a certain complexity of design, is that four identical slopes seriously “eat up” the volume of the attic, which complicates the organization of the “inhabited” area in it. To create a residential attic, one has to sharply increase the steepness of the roof and resort to "inserting" additional windows and superstructures. It is clear that it is simply pointless to take on the calculation and construction of such a complex structure on your own, since it requires highly professional architectural design and installation.

The main elements of the tent truss system

Consider the basic structure of the hipped roof truss system. To do this, we first take a completely abstract house, the walls of which form a square, and try to try on such a roof for it.

In the context of this article, we are not particularly interested in roofing and walls. We will hide them from sight in order to remain “one on one” already with, in fact, the very design of the truss system. Well, then consider it in detail.

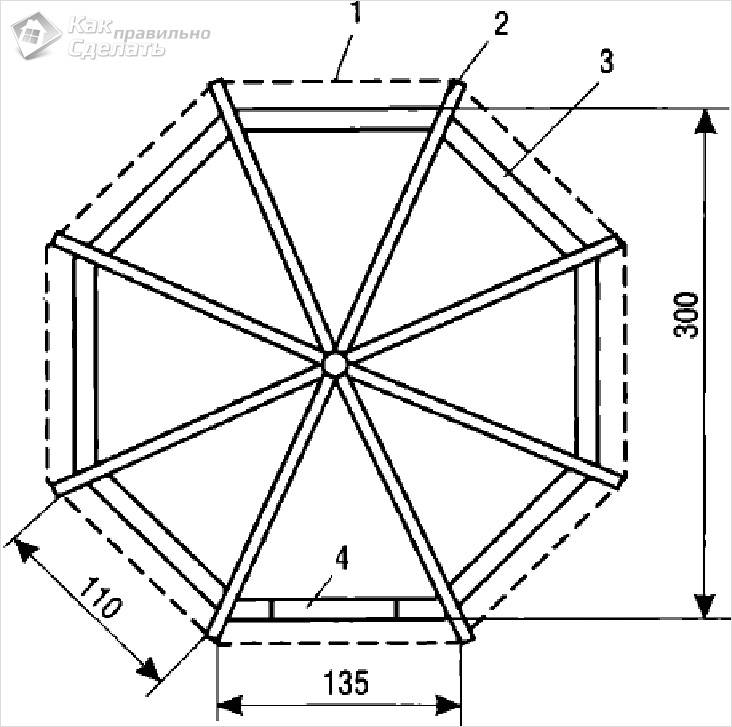

The walls are hidden from view, but the mauerlat is left (pos. 1). This is a powerful beam, which is fixed with a belt along the upper end of the walls - it is on it that all the rafters will rest. Unlike, for example, a gable roof, the Mauerlat in our case must be a necessarily closed frame, rigidly connected - the strength and stability of the entire truss structure directly depends on this.

From the corners of the Mauerlat up to the center, to the ridge knot (pos. 3), the edges of the pyramid converge - their role is played by the rafters (pos. 2). These are the longest and most loaded of all the other rafter legs, and usually the most “powerful” lumber is used for their manufacture - this will be discussed below. On the pyramid drawing, they correspond to the segments [KA], [KV], [KS] and [KD]. The length of the layered rafters in the same diagram is indicated by Ln.

From the center of each side to the same ridge knot, the central rafters (pos. 4) pass. They determine the height of the isosceles triangle of each slope. In the drawing, this is, for example, the segment [KE] (rafter length - Lc). In geometry, to designate this element of the pyramid, there is a separate name - apothem.

Finally, shortened rafters or sprigs (pos. 5), installed with a certain step, depart from each slanted rafter leg in both directions to the Mauerlat. Their number will depend on overall dimensions the entire system.

By the way, often in order not to “overload” the ridge knot with connections, they refuse to install the central rafters, and only the rafters are mounted, placing them symmetrically to the apothem.

This diagram shows an option in which all the rafters, without exception, from the slanting to the shortest rafter, are made with a protrusion beyond the Mauerlat - to create the necessary cornice overhang. But in the future, all calculations will be carried out for the “clean” length - from the ridge bridle to the Mauerlat, and the elongation will be calculated separately, depending on the planned overhang width and slope angle.

Very often they do this - a powerful rafter beam ends on a Mauerlat, and the cornice light is provided by increasing the length due to special details - fillies from thinner boards. This allows you to achieve considerable savings on lumber.

The diagram showed one of the simplest schemes, when the rafters were made according to a hanging scheme, and completely balanced. To be honest, this is very rare in reality. In practice, it is necessary to resort to the installation of additional, reinforcing elements that ensure the strength and stability of the structure of the truss system.

Firstly, the rafters can be installed on a layered system, that is, supported by a central post. The rack can rest on the main inner wall (if there is such an opportunity), or on a bed laid in the center - a powerful beam based on opposite outer walls of the building.

1 - rafters;

2 - central pillar (headstock);

3 - puffs (crossbars).

By the way, when erecting light buildings, for example, gazebos, sometimes the central post is located along the entire height, from the foundation (floor) to the ridge knot, and serves as a kind of "interior" item.

Another option - the basis for the rack are horizontal puffs (crossbars) connecting opposite rafters. These puffs can be located at the bottom, closer to the Mauerlat, or approximately in the middle of the height of the "pyramid". Sometimes such crossbars serve as the basis for filing the roof of the attic.

The figure shows an example when the sloping rafter legs (pos. 1) are diagonally tied with puffs (pos. 5). At the intersection of the puffs, a central support (pos. 4) is mounted. All rafters, including the central ones (pos. 2), are connected on a support (headstock), thereby forming a ridge knot (pos. 3).

Often the B-pillar is not used at all. On small roofs, the rigidity of the structure is ensured simply by the reliable fastening of the central and slanting rafters on the Mauerlat and in the ridge knot. In the ridge, the rafters are adjusted to each other by sawing at a certain angle, and then this connection is reinforced with metal overlays. Another option is to use a central insert element to which the rafter legs are attached.

But with large lengths of rafter legs sometimes - and sprigs, they still require reinforcement. For this, additional elements of the system can be used.

This illustration shows one of the options. In the center of the square formed by the Mauerlat (pos. 1), a bed (pos. 2) is embedded. As in the usual scheme, slanting (pos. 3) and central (pos. 4) rafters and sprigs (pos. 5) are installed.

From the bottom of the slanted rafter legs, cranial bars (pos. 6) are reinforced - they serve for more reliable support for installed sprigs.

Both the central legs and the sprigs are connected to the opposite, symmetrically located parts with the help of ties (pos. 7). The screeds of the lower row, in order to exclude deflection in the center, rest on the bed, and at the same time serve as a support for the upper row perpendicular to them.

From the screeds to each central rafter leg and to the sprigs there are vertical racks (pos. 8).

Instead of vertical racks (or together with them), struts can be used - supporting elements located at an angle to the horizon. This is convenient when the main load needs to be shifted to one central point (for example, a bed or a capital jumper inside a building), and not distributed by puff. The struts are usually placed at an angle of 45 ÷ 60 °. They find application if the length of the rafter legs exceeds 4.5 meters. Such additional support points make it possible to reduce the cross-section of lumber used for the manufacture of rafters, that is, to facilitate and reduce the cost of the entire system design.

The illustration shows two options. On the left - combined, in which both the stand (pos. 2) and the struts (pos. 3) are fixed to the bed (pos. 1). In the right figure, they did without a rack, and only two struts rest against the bed, going up to the symmetrical rafter legs.

The diagram also shows the connecting parts - metal pins (pos. 4) and steel brackets (pos. 5).

As already mentioned, the longest and most concentrated loads are the diagonal (diagonal) rafter legs. Not only are they usually thicker than others - they often have to be additionally propped up to prevent deflection or torsion. For this, the same struts can be used, extending from the central bed, or a special unit of the system, called a trussed support.

This node is a trussed beam (pos. 9) that cuts into the Mauerlat at the corner, and from which the stand (pos. 10) goes vertically upwards, supporting the slanting rafter leg. Sometimes, on large roofs, it is necessary to install on just a trussed truss, but on a trussed truss, that is, to strengthen the vertical strut with struts.

There are other options for mounting and strengthening the hipped roof truss system - many craftsmen use their own, proven and proven methods over the years. But the basic principle still remains the same as shown above.

Now it is necessary to consider a block of issues related to the linear dimensions of the main structural parts, with the section of lumber necessary for their manufacture, with other geometric parameters of the system being created. In a word, you need to dive into the calculations.

Carrying out basic calculations of the hipped roof truss system

Carrying out the proposed calculations will help the owners to determine in advance the main characteristics of the future roof and the required amount of materials. Calculations must be carried out in a certain sequence, since most of the parameters are closely interconnected, and, one might say, follow one from the other.

The height of the "pyramid", the slope angle of the slopes and the planned roofing of the hipped roof

This group of parameters is highlighted in the first place. The listed characteristics are closely interconnected and will be decisive for the rest of the calculations.

Why is it necessary to know the steepness of the slopes in advance? Yes, if only because each owner sees in advance the roof of his future home, “dressed” in one or another roofing that he prefers. And when choosing coatings, you want it - you don’t want it, but you have to comply with certain requirements - each material has its own maximum permissible limits for the minimum slope.

The fact that the slope depends on the height of the top of the “tent” (and vice versa) probably does not have to be explained - with the growth of one parameter, the second also increases. But only the dependence here is not linear, but tangential. Let us turn to the diagram of the drawing of the "pyramid".

The height of the ridge knot is indicated H- this is a segment . This top itself in a horizontal projection lies exactly in the middle of any of the sides of the square that forms the base. It turns out a right triangle KFE, leg which is known is half the width (length) of the building [AB]. Roof pitch angle α . It is easy to determine the height:

H = 0.5 × [AB] ×tga

This calculation will be easier to make using the built-in calculator: