The roof of the house with an attic do it yourself. Rules for creating a reliable floor in the attic in a private house. roof truss elements

truss system mansard roof

More and more architectural, original houses appear, decorated with bay windows, superstructures, mezzanines. Attics are coming into fashion, expanding the useful area of \u200b\u200bthe house. But mansard roofs, unlike a simple gable roof, require complex truss systems. Correctly calculating them and installing them is not at all easy. Below we will try to briefly highlight this issue and give useful advice specialists.

Luckily, no injuries occurred, but sections of the attic's concrete deck broke and had to be repaired. The new wooden decks were then topped with #30 asphalt concrete and North Country Black Slate, installed with copper nails. Pressurized nailers were installed at the junction of the attic mansard and flat copper roofs and along the hips. Metallic brass and a decorative ridge of metal were installed over the nails.

Installation of truss elements

With the scaffolding in place, Wagner Kroffing was able to take a close look at the 13-foot eight-foot decorative skylights, fascia, and built-in copper gutters. The 13 attics were determined to be in need of restoration and the fascia and built-in gutters to be replaced, which means carefully copying all the details exactly as they were made 100 years ago.

At the design stage of the house, the roof structure should be calculated. Calculations using complex formulas should give the value of the load per meter of a square truss system. For residential buildings, the normative load is 50 kg / m2.

The State Office for Historic Preservation was called upon to control and approve all decorative details before they could be installed. The approval process often took several weeks. In many places the copper has worn out and most of the solder joints have either chipped or cracked from the weather and wear and tear over the last 104 years.

Hearing aids have been carefully handled to ensure they are not damaged. The scaffolding surrounding the skylights had to be removed from two decks at the same time, so Wagner Croweather could make a hole large enough to remove the skylights from the windows and pull them up to the upper deck, which was the only place they could be lowered to a safe ground . During this operation, the workers were tied down with general purpose harnesses, straps and fall protection ropes.

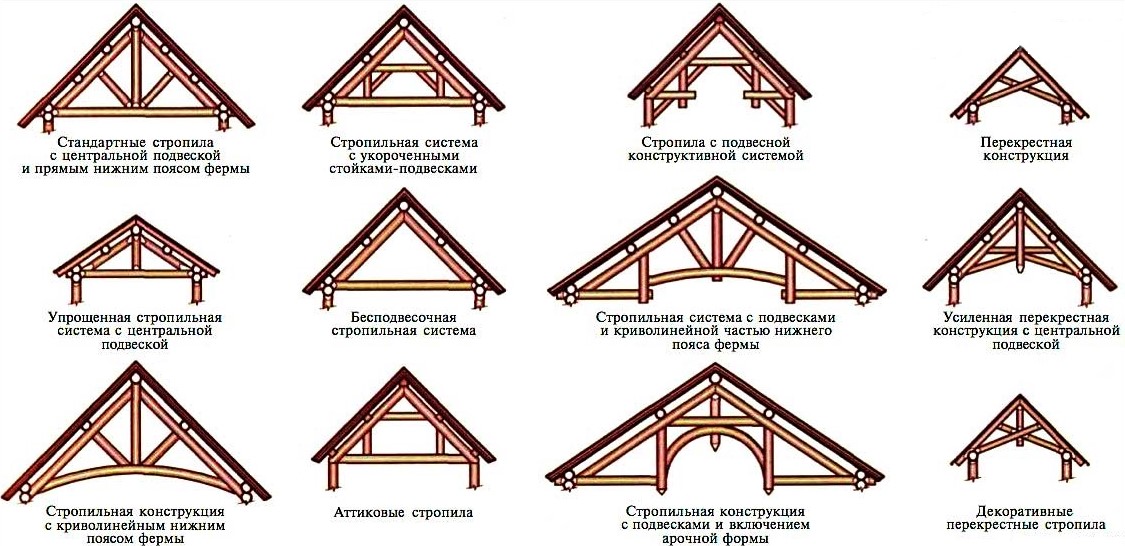

In accordance with the calculations, the type of roof structure of the attic is selected. The main varieties include:

- hanging rafter system;

- sloping roof rafter system;

- layered gable roof system;

- combined.

The most common are the combined rafter systems of pitched roofs. It is recommended to entrust the calculation of complex truss systems to professional designers.

The State Historical Preservation Service wanted the hearing aids to be salvaged and rebuilt with the original patina copper for historical and aesthetic reasons, once in his metal shop, Wagner Kroffing had to go into detail about how he would repair the hearing aids and submit them to the State Service for the preservation of historical monuments. After several hours of deliberation by Wagner Kroffing and Gary Vot, a sheet metal expert from Texas, it was decided to replace the round copper window stoppers and top crickets with new 20 ounce copper tin and reposition the backs of the dormers decorative fronts with new 20 due to the fact that these dormer the parts were the least visible from the ground and quickly patinated.

Advice!

To increase the useful area of the building, you should choose the design of a multi-pitched mansard roof.

roof truss elements

Experienced professionals will perfectly understand what in question in the article, because they know all the terms and names of structures. In order to make it clear to everyone, here are the common names of the mansard roof structural elements:

Each hearing aid took about 120 man-hours to remove, repair and reinstall. The result is decorative hearing aids that look 100 years old but are durable and waterproof. “The most rewarding part of the project was translating the huge ornate skylights so that the existing façades remained, but all the integral interior highlights were new,” says Morgan.

Floor insulation in the attic

The existing copper along the bases was carefully removed and new copper pads were installed. Since there were no nails or wooden decks on the original roof's concrete deck, the copper mansards had to be modified to accommodate the change in deck height.

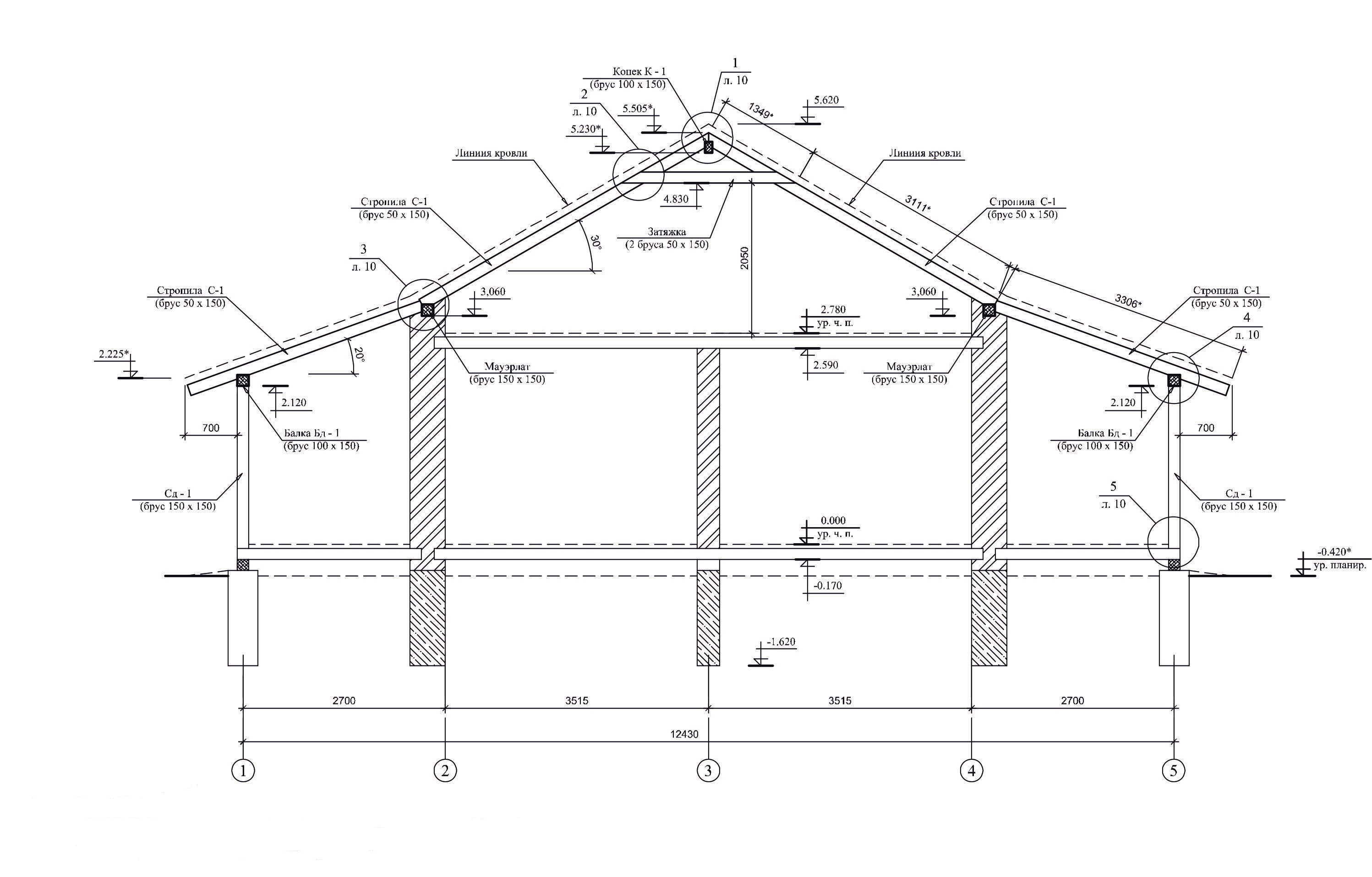

- Mauerlat - a beam fastened along the upper crown or along the wall of the house, on which the rafter system rests;

- Floor beams - a wooden structure that plays the role of an attic floor and, at the same time, the ceiling of the underlying room;

- Racks - vertically mounted pillars on which rafters and beams are attached.

- Runs - beams (boards) located horizontally, serve as a support for the rafters;

- Rigel - horizontal beams in a U-shaped truss. They serve as a support and pull together the pitched rafters, have another name "puffs";

- Rafters - timber or boards that form the basis of the roof structure;

- Suspension - a rack, the task of which is to support the crossbar, facilitating its work, is also installed horizontally;

- Lathing - a plank or plywood base on which roofing material is laid;

- Filly - a board that serves as the basis for mounting the overhang, is installed at the bottom of the truss system.

A recessed copper trough was created on one side of the skylight dormer to properly shed onto the new flat seamed copper roof. Both parts were duplicated to exact dimensions, but installed using a safer stealth removal method than originally used.

The Wagner Roof also renovated the clock tower. The work consisted of repairing the weathered Buckingham slate and copper weather vane and replacing the semi-circular gutters, leaded copper tables, and copper-plated copper roof. The lead-plated copper tables were made locally and replaced when the masons replaced the stone urns. The flat, seamed copper roof had multiple views, and the clock tower's open configuration was a challenge. About 90 percent of the lead-coated copper panels were flattened with corner cuts.

Elements of the truss system

Rafter system calculations

The choice of truss structure largely depends on the size of the building, in accordance with which the span length is determined, i.e. distance between main posts. For small houses, preference can be given to a gable design.

Their staff and project managers did an excellent job with this challenging project. Do you know the condition of the roof should be checked at least once a year? Winter is the enemy of the roof and everyone knows that. So, to prepare before it happened. The summer holidays have decreased and now we have the opportunity to take care of that part of our house that takes care of our safety and comfort on any day of the year.

Even the highest quality roofing materials have a life of their own. This life, however, can be saved for as long as possible if you know a few basic roof maintenance and repair rules and take care of it properly.

Gable roof truss system with attic

Structural calculations are carried out in order to determine the load, in accordance with the standards and building regulations. The main rule for a mansard roof is to limit its height, which should not be less than 2.5 meters indoors. Thus, the roof must be at least 2.80 m high, since it requires the laying of an insulating layer, and finishing inside the attic itself.

Attic roof installation technology

What we can do? - The so-called "jump" roof is a very common practice in which the tiles are lifted one by one and look around carefully for injury or damage. Elevating allows them to look everywhere and wood trellis underneath and foil loft. And if hail damage tiles can be easily replaced, the rest good time to think about and decide whether we want to do repairs every year or once and for all. If the latter - let's bet on the solutions that provide our decades of peace.

Gable roof structure

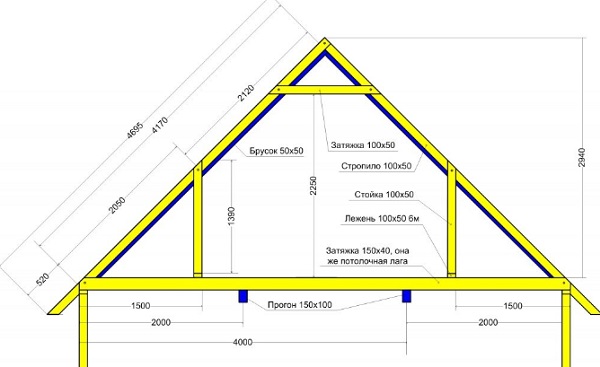

Be sure to make a design drawing, on which you should put down all the dimensions and display the elements of the frame as much as possible. The drawing should show the dimensions of the house, the angle of the rafters, the height of the roof.

If it turns out that the grill is "scum" - he must check whether moisture is damaged, got under the tiles due to broken tiles or the general patterns that we use do not allow the tiles to "grip" well within the framework and leak. Another possible cause is the wrong arrangement so as to reliably conduct rainwater or simply to save elements such as snow-retaining brackets that would not allow tables to slide on snow and damage the tiles and eaves below them, if any.

A very common reason is poor installation of roofing materials such as foil, the function of which is to hold the entire attic wood grill onto the wood siding. The name has become a household name under the roof "black paper" is used to place all types of roof foils under one common denominator allow you to "insert" very poor materials in this category. Such bad materials of dubious origin have not ruined a single roof, and statistics show that more than two-thirds of the roofs in Bulgaria are “dressed” with them.

Advice!

To spend accurate calculations for all loads on the roof and its elements, it is recommended to use the calculator posted on many sites dedicated to the construction of roofs.

It is enough to enter the type of roofing, the material of the mansard roof frame and dimensions. The program will calculate the cross-sectional angles and rafter spacing, give recommendations on the design of the crate.

Very often we have seen roofs whose roof coverings have literally become dusty over time or have even "disappeared". The main functions of roofing foils are not limited to interrupting the passage of moisture from outside to inside. Little is known, but it is absolutely necessary that the function lead generated by human activity under the roof of water vapor inside out. Because this moisture damages the very structure of our roof. So films that perform this function are called "vapor diffusion.".

Installation of support posts and girders

The most basic indicators that one such film must meet are. Well, once we know what to do with our roof, we can be sure of the high quality we will get. And while we upgrade with high quality materials and replace the entire roof, it's good to look at what a complete roof system is and invest in long term solutions with at least 33 years warranty. Because it's the only way we'll be away from renovations for a long time, and we'll have time for ourselves, family, friends.

Calculation of the truss system

Attic roof installation technology

You should start with the installation of a Mauerlat, which is laid along the perimeter of the upper edge of the walls, if the house is brick or block. In houses made of timber or chopped with Mauerlat, the upper crown can serve. The beam from which the Mauerlat is made must have a cross section of 100x100 mm or 150x150. Softwood for timber should be well dried. Mauerlat beams are fixed with anchors or studs to the walls in increments of about two meters. Under the Mauerlat, waterproofing is installed, as a rule, of a roll type (roofing material).

Next, proceed to the installation of the ceiling. Beams 150x200 mm, laid on the Mauerlat, should protrude from the walls of the house by about 0.3-0.5 m. The beams are fixed with corners and screws (wood screws), starting from the extreme, then intermediate.

Important!

When laying, use a cord to control the horizontal level so that the beams lie in the same plane.

The distance between them, as a rule, is 0.5-1.0 meters, if it is planned to lay insulation, the standard sheet width of which is 0.6 m, then it will be more convenient to withstand the same step of the beams.

Roof truss installation

Installation of support posts and girders

The next step is the installation of racks. For them, a bar 100x150 mm is used, the fastening of which is carried out on the front floor beams. It is necessary, using a plumb line, to align the verticality of each support and fix it with jibs. Intermediate supports are also installed on the beams strictly vertically, forming two parallel rows.

Intermediate supports of the roof truss system

This is followed by the installation of runs, which can be made from a board 100-150 mm wide and 40-50 mm thick. Fixing the runs is done with nails and corners on the screws. Then, on top of the runs, plank crossbars are laid, for rigidity, mounted on the end.

The purlin beam forms a cantilever for supporting the diagonal roof rafters

Advice!

As a result, the contour of the future attic space is formed. To give additional strength, the supports should be strengthened with struts and contractions.

Roof truss system

Installation of truss elements

Installation of rafters, starts from the bottom. For them, a board 40-50 mm thick and 150 mm wide is suitable. With one end we rest on the Mauerlat close to the floor beams, and the other is attached to the girders with the help of corners, screws and nails. To install the rafters in the upper part of the roof, mark the center line of the roof. All rafters must be the same length. To do this, make a template board by making cuts on it from both ends. After that, according to the template, you can saw off the rest of the rafters.

rafter legs

The rafters are mounted on girders, fixed in the upper part with metal plates. On the runs, the beams are fixed with cuts point-blank and fixed with corners on self-tapping screws.

Rafter system fastening

For strength, the lower rafters should be reinforced with struts (board 50 × 150 mm). After fixing the struts, temporary stops can be removed.

Often the elements are connected not only with carpentry knots, but also with the help of fasteners.

Rafter installation

In cases where floor beams are laid in wall pockets, fillets should be fixed on the lower rafters for the roof overhang. If the floors lie on the Mauerlat, then fillies are not needed, since the beams should protrude beyond the walls forming an overhang.

Sheathing is an important part of the roof structure.

The crate is installed depending on the intended coverage of the mansard roof. Either the crate will be solid, or with gaps. A waterproofing layer should be laid on top of the crate, after which you can start sewing gables and laying roofing material - metal tiles, corrugated board or slate.

Roof deck under metal tile

If the attic roof has broken structure, then, as a rule, it is not insulated, since the air gap under the rafters protects the premises, while simultaneously ventilating the under-roof space. To do this, when sewing up the gables, you should leave ventilation windows (holes) above the attic floor. Thermal insulation should be done only inside the attic.

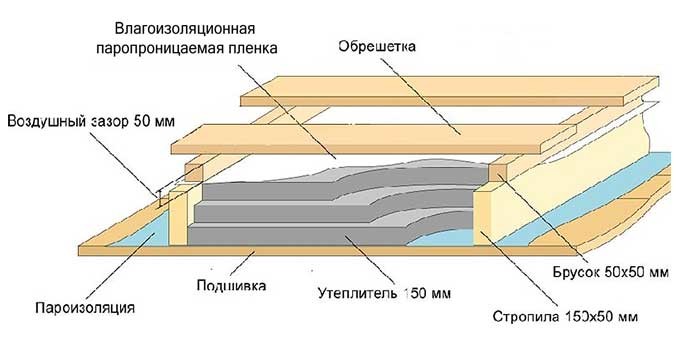

Mansard roof insulation

The attic thermal insulation device has its own characteristics, since the rooms have triangular or trapezoidal ceilings. Builders consider insulation one of the most difficult technological tasks in the construction of attic spaces. The main thing is to lay the thermal insulation so that it does not shrink during operation on the sloping ceiling and on the fences.

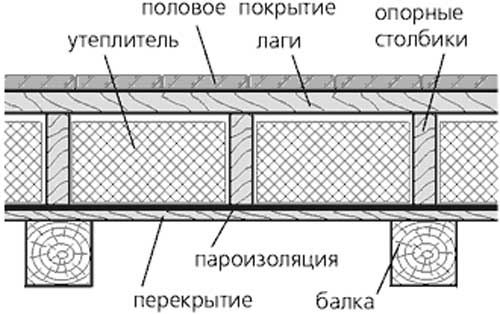

The attic floor is a very economical and practical option. In fact, this is an attic space under a pitched roof, which is fully exploited, on a par with an ordinary floor. Everything matters structural elements this floor to perform correctly so that it functions for a long time and correctly.

The attic device begins with a design solution. It is necessary to find out what will be the next floor, what structures and materials will be used in the construction, as well as determine the load-bearing and enclosing structures. The entire base on which the attic will be built is also taken into account.

Roofing attic floor

After all decisions are made, the future layout is approved, the stage of laying the floors begins.

It is important to consider the design and arrangement of the attic floor

This step is very important because cover provides stability, perceives and transmits loads. These elements of the structural system are made from standard, typical parts. A universal system for attic floors will be overlapping on wooden beams.

Wooden elements must be free of rot, cracks and similar flaws. Beams are usually placed in increments of 60 cm - 120 cm. The larger the dimensions of the room, the denser the beams are laid. They are located perpendicular to the length of the entire building.

The layout starts from the edges of the building, moving towards the center. In the outer walls leave special niches or grooves, from fifteen to twenty centimeters long, in order to lay the element in this recess. Fastening occurs with the help of anchors.

Scheme of insulation of floors of the attic floor

Fill the inter-beam space with roll-over shields or lightweight concrete panels, and also be sure to lay heat-insulating and sound-proofing materials. A reinforcing mesh is placed on top of the insulation, and then all this is poured with a cement screed, which will become the basis for the future floor covering.

Often-ribbed ceilings made of reinforced concrete beams and hollow foam concrete, expanded clay or gas silicate blocks are also used. These structures are quite easy to install and do not need formwork, they have high quality characteristics, also can be hidden in these communication blocks.

The layout of the floor beams of the attic floor

To begin with, along the perimeter of the load-bearing walls make a belt of monolithic concrete, approximately twenty centimeters high. Overlappings lead into this belt about eight centimeters deep, and the space is filled with blocks. The reinforcing mesh is laid out on top of the blocks and beam elements. Next, this surface is poured with concrete.

Only after two weeks is it possible to continue work on attic floor then the concrete will be strong. In order for the floor to be strong and the bearing capacity to be high, it is necessary to reinforce the concrete filling.

Roof structure

The truss system is the main element of the roof, it should be reliable and durable so that the attic room lasts a long time and correctly. The slope of the roof is determined according to the proportions of the entire building in order to create an overall harmony. appearance the buildings.

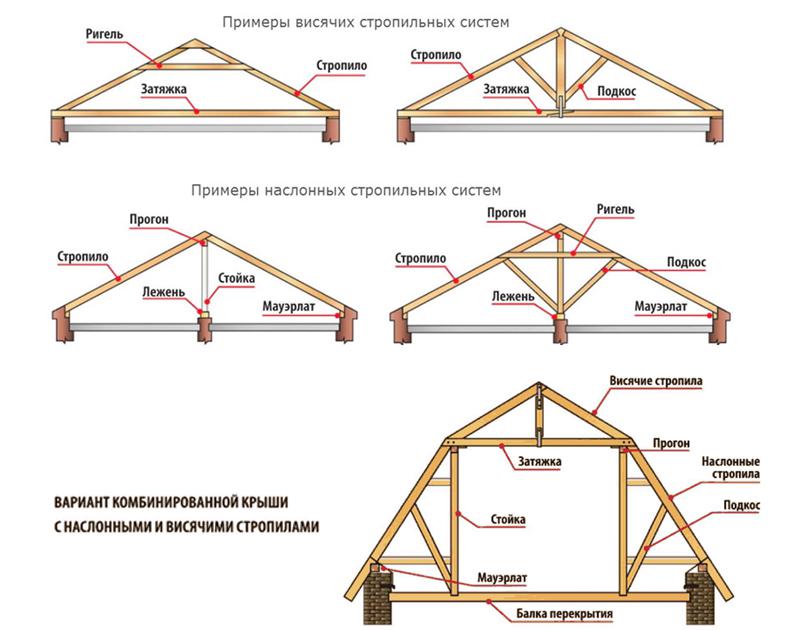

Two types of rafter systems are used, using layered rafters or hanging rafters. The support of the layered rafters occurs by resting with one end on the outer wall, namely in the Mauerlat, and with the other on the intermediate support.

The design of the attic roof in the form of a diagram

For the correct operation of this structural system, all loads must be correctly calculated, and the building must also have load-bearing walls, on which lean on one end of the rafter leg. If the building is small and oversized, hanging rafters are usually used, since they do not need load-bearing walls. One end of the rafter leg rests against the wall, namely on the Mauerlat, and the other end against the other rafter leg, without additional support.

The dwelling must be equipped under a reliable roof structure. This design must withstand skylights, the load from layers of thermal insulation, sound insulation and vapor barrier.

It is important to remember about the thermal insulation of this room, since most of the heat is lost through the roofing. From inside the premises are laid with vapor barrier, then a layer of insulation, most often mineral wool, and then comes a layer of waterproofing.

It is important to make the necessary gap for ventilation in the roof between the layers so that condensation does not form, which can lead to wooden elements structures to decay.